Oxy-Fuel Combustion Technology

Oxy-fuel combustion is an innovative carbon capture technology that involves burning fuel in a pure oxygen environment instead of air, resulting in a highly concentrated stream of CO2 that is easier to capture and store. This process offers significant advantages in reducing greenhouse gas emissions from power plants and industrial facilities.

Process Overview

The oxy-fuel combustion process consists of several key steps:

1. Air Separation:

Oxygen is separated from air using an Air Separation Unit (ASU), typically through cryogenic distillation.

2. Combustion:

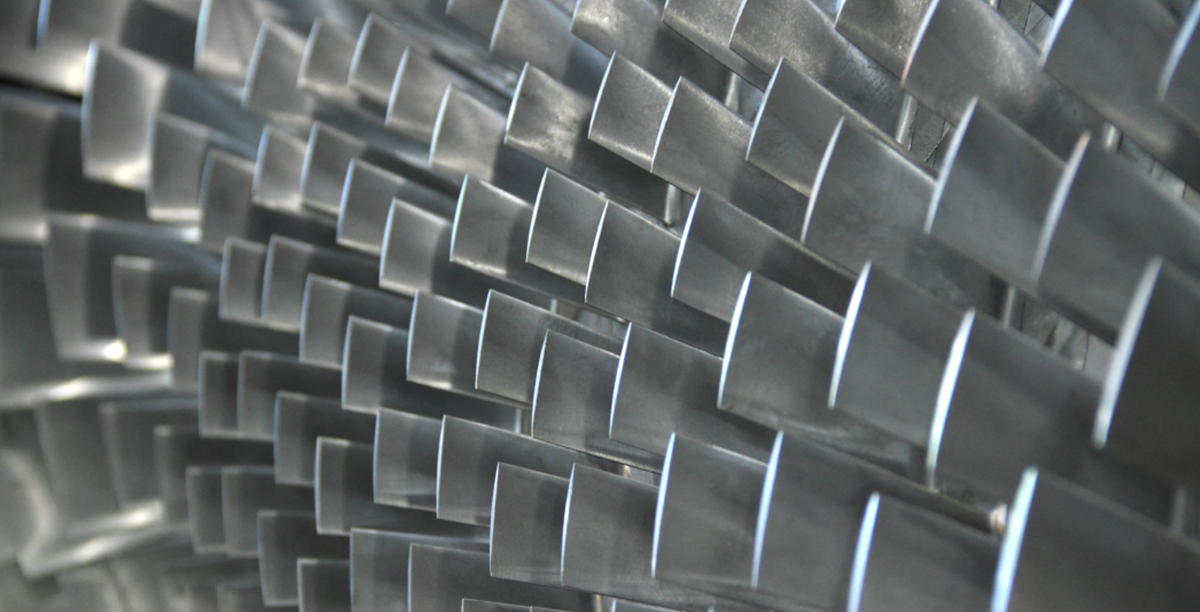

The fuel (coal, natural gas, or biomass) is burned in a high-purity oxygen environment, often mixed with recycled flue gas to control combustion temperatures.

3. Flue Gas Processing:

The resulting flue gas, primarily composed of CO2 and water vapor, undergoes cooling and condensation to remove water.

4. CO2 Purification:

The concentrated CO2 stream is further purified to remove any remaining impurities.

5. Compression:

The purified CO2 is compressed for transport and storage.

Key Advantages

1. Oxy-fuel combustion produces a flue gas stream with CO2 concentrations of 70-95%, compared to 12-15% in conventional air-fired systems [1][2].

2. The high CO2 concentration simplifies the capture process, potentially reducing overall capture costs.

3. The absence of nitrogen in the combustion process significantly reduces NOx formation [2].

4. Oxy-fuel technology can be retrofitted to existing power plants, though with some modifications [3].

Challenges and Ongoing Research

1. The air separation process is energy-intensive, which can reduce overall plant efficiency.

2. Combustion in pure oxygen results in extremely high temperatures, requiring flue gas recirculation for temperature control [1].

3. The high CO2 and water vapor concentrations can lead to increased corrosion in boilers and other equipment.

4. The capital and operational costs of air separation units and other specialized equipment remains a challenge for widespread adoption.

Research efforts are focused on addressing these challenges through:

- Developing more efficient air separation technologies

- Optimizing combustion processes for oxy-fuel conditions

- Improving materials to withstand high-temperature, high-CO2 environments

- Exploring pressurized oxy-combustion systems for enhanced efficiency [2]

Applications and Future Prospects

Oxy-fuel combustion is particularly promising for:

- Coal-fired power plants

- Natural gas combined cycle plants

- Industrial processes such as cement and steel production

As research progresses and costs decrease, oxy-fuel combustion is expected to play an increasingly important role in global decarbonization efforts. Its ability to produce a high-purity CO2 stream while significantly reducing other emissions makes it a valuable technology in the transition to a low-carbon future.